- Čeština

- Español

- Italiano

- Deutsch

- Polski

- Français

- 日本語

- Home

- Troubleshooting

- Print Quality Troubleshooting

- Failing supports

Failing supports

- Print Quality Troubleshooting

- Bad looking surface above supports

- Broken supports (SL1/SL1S)

- De-lamination / separated layers (SL1/SL1S)

- Failing supports

- How to prevent failing supports

- Firmware update failed #10534 (SL1)

- First layer issues

- Ghosting

- Holes in print (SL1/SL1S)

- Layer separation and splitting FDM

- Layer shifting

- Object missing details

- Poor bridging

- Print detached from supports (SL1/SL1S)

- Print doesn't appear / Resin does not solidify

- Prints breaking away from the platform

- Problems with infill

- Removing and object stuck to the bottom of the tank

- Sample G-codes

- Scratches/bubbles on prints (SL1/SL1S)

- Skewed / deformed prints (SL1/SL1S)

- Stringing and oozing

- Temperature sensor failed #10205 (SL1/SL1S)

- The Benchy hull line

- Under-extrusion

- Visible layers (SL1/SL1S)

- Warped layers (SL1/SL1S)

- Warping

- Watertight prints

- Printer troubleshooting

- QR Error codes

- Print Error Messages

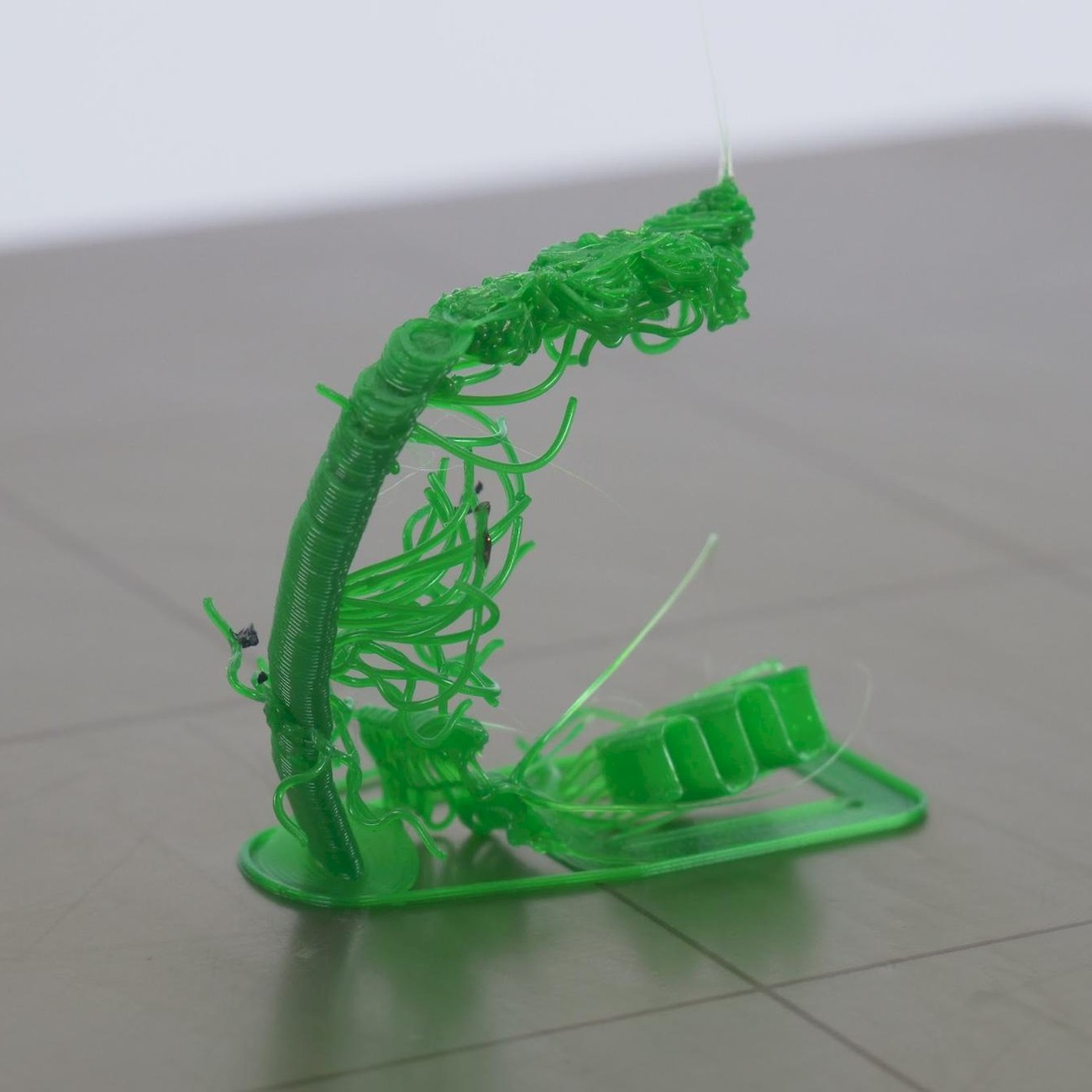

Supports are an important part of a 3D printed object, especially when you need to print complex models. So when the supports fail (break) like in the picture above, it usually affects the rest of the print. Most often, the print won’t finish successfully.

Supporting pillars, especially when using low support density, can be quite fragile and not very stable things. The taller (and thinner) the supports, the higher the danger of failure.

In places where you have big overhangs, supports should be added. Although some overhangs can be printed without supports, in many cases supports are required and the print won’t finish successfully without them. For overhang tests, you can download STL models from our platform here.

How to prevent failing supports

- Avoid isolated support towers, Cut printed objects to more parts.

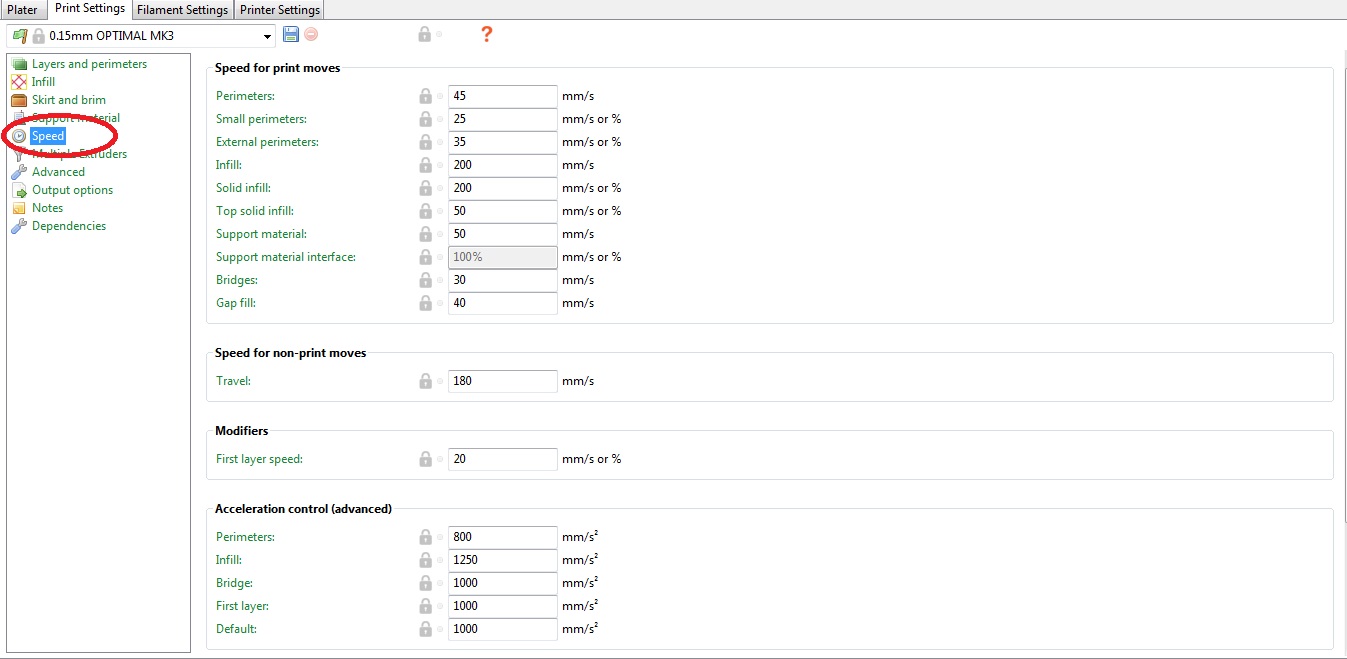

- Reduce printing speed for supports in PrusaSlicer, section Print settings – Speed

- Use a Brim around our support, found within Print settings – Skirt and Brim

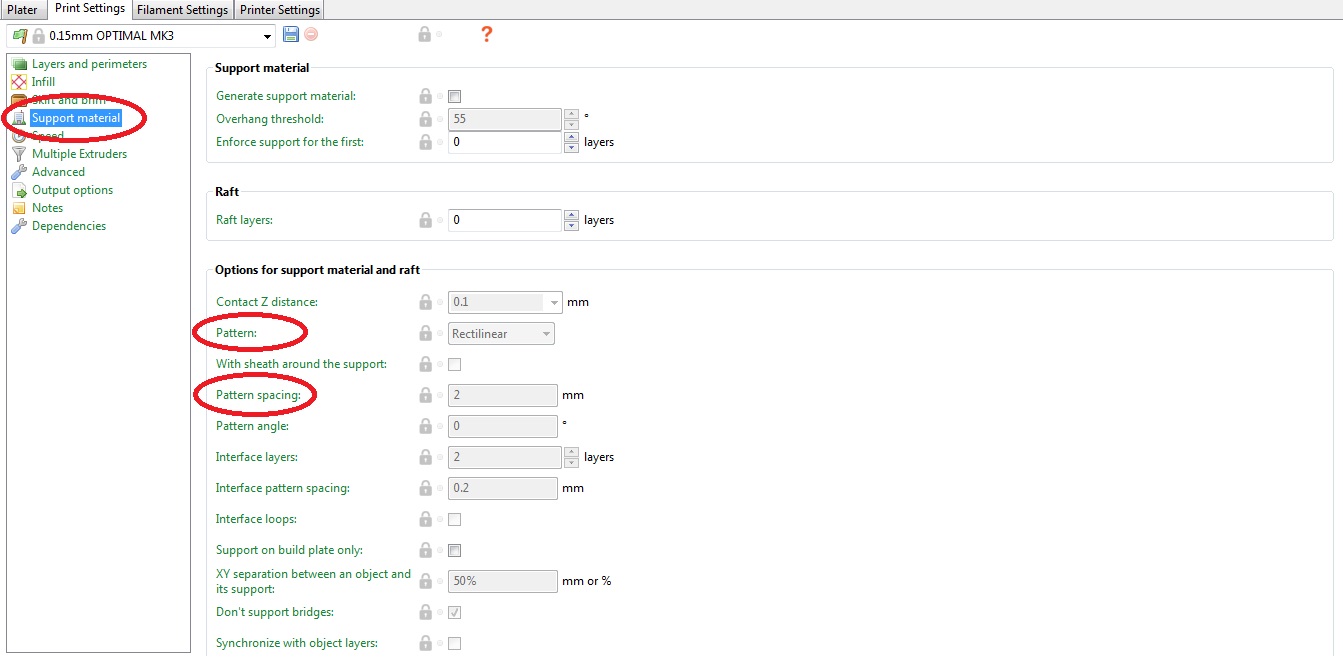

- Use a different 'pattern' of the support. in PrusaSlicer, section Print setting – Support material – Pattern.

- Change the value of the Overhang Threshold. The Overhang threshold value represents the most horizontal slope (measured from the horizontal plane) that you can print without support material (90=vertical).

- Use custom supports, tailored to your model.

Speed Settings location

Support Settings location

Comments

Still have questions?

If you have a question about something that isn't covered here, check out our additional resources.

And if that doesn't do the trick, you can send an inquiry to [email protected] or through the button below.