- Čeština

- Español

- Italiano

- Deutsch

- Polski

- Français

- 日本語

- Home

- Troubleshooting

- Print Quality Troubleshooting

- Stringing and oozing

Stringing and oozing

- Print Quality Troubleshooting

- Bad looking surface above supports

- Broken supports (SL1/SL1S)

- De-lamination / separated layers (SL1/SL1S)

- Failing supports

- Firmware update failed #10534 (SL1)

- First layer issues

- Ghosting

- Holes in print (SL1/SL1S)

- Layer separation and splitting FDM

- Layer shifting

- Object missing details

- Poor bridging

- Print detached from supports (SL1/SL1S)

- Print doesn't appear / Resin does not solidify

- Prints breaking away from the platform

- Problems with infill

- Removing and object stuck to the bottom of the tank

- Sample G-codes

- Scratches/bubbles on prints (SL1/SL1S)

- Skewed / deformed prints (SL1/SL1S)

- Stringing and oozing

- Stringing from material left on the nozzle

- PrusaSlicer settings

- Filament

- Hotend

- Enough settings, pass me my heat-gun!

- Temperature sensor failed #10205 (SL1/SL1S)

- The Benchy hull line

- Under-extrusion

- Visible layers (SL1/SL1S)

- Warped layers (SL1/SL1S)

- Warping

- Watertight prints

- Printer troubleshooting

- QR Error codes

- Print Error Messages

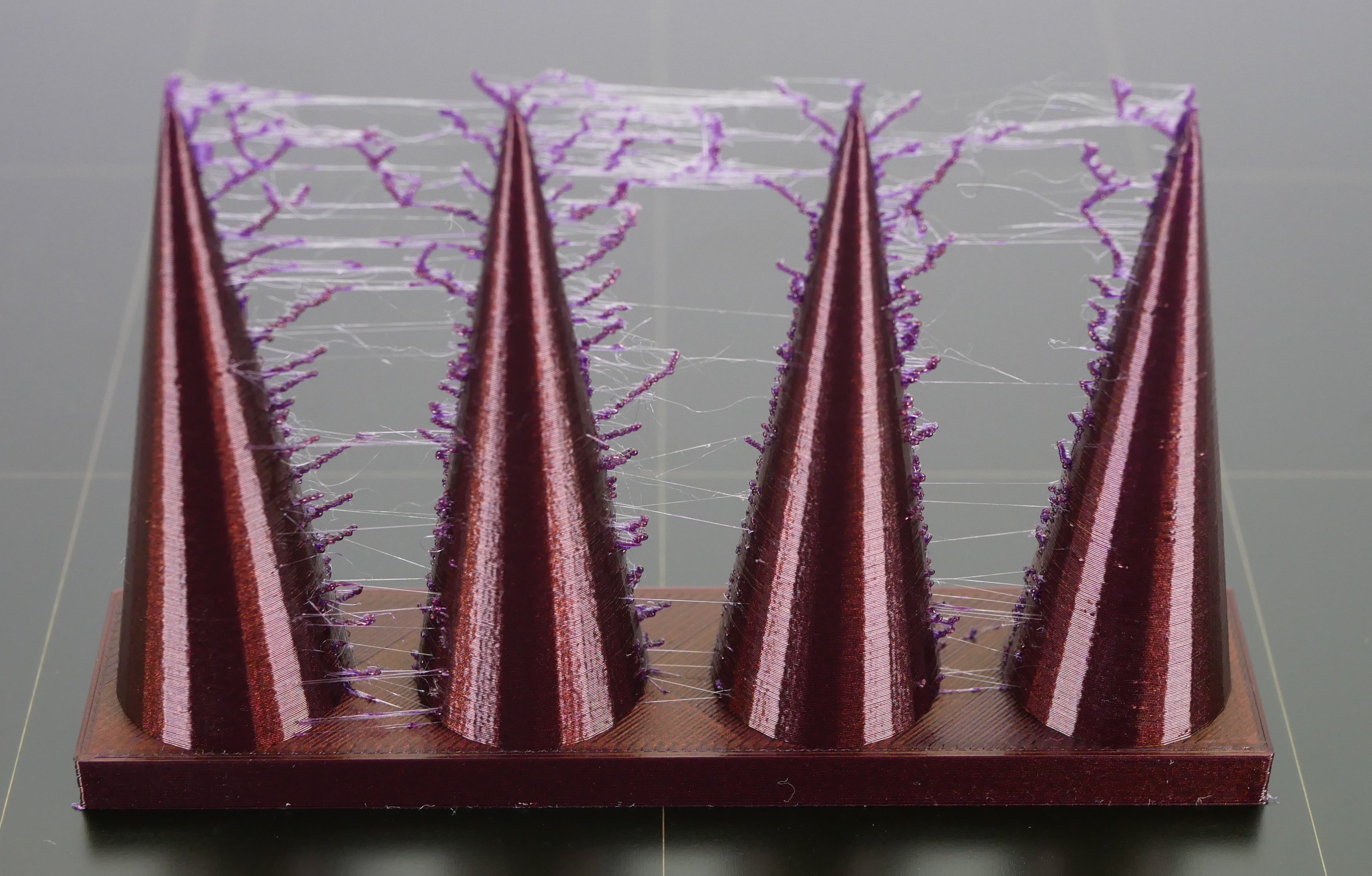

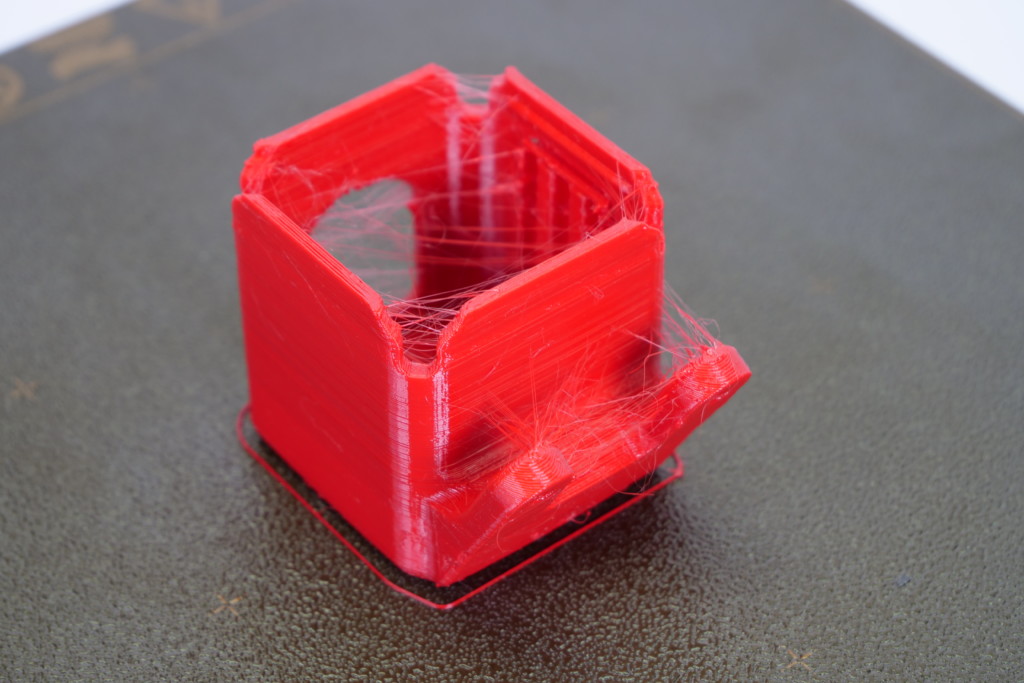

Stringing or oozing, also known as "hairy prints", is the name given for when small strings of filament are left on a printed model. This usually happens when the filament keeps flowing from the nozzle while the extruder is moving to another object. You can see this as a marginal line of filament left between the objects.

This issue is caused by very high printing temperatures and/or using incorrect retraction settings. This can be solved by changing a couple of settings in PrusaSlicer and checking your hardware.

|  |

Stringing from material left on the nozzle

If you print for a long time from a single type of filament, such as PET-G, the filament can create a thin layer in the nozzle. This can cause stringing as the strands of the filament stick to the surface of the print. Therefore, thoroughly clean the nozzle before printing and make sure that any dirt or remnants of previous filaments are removed from the nozzle.

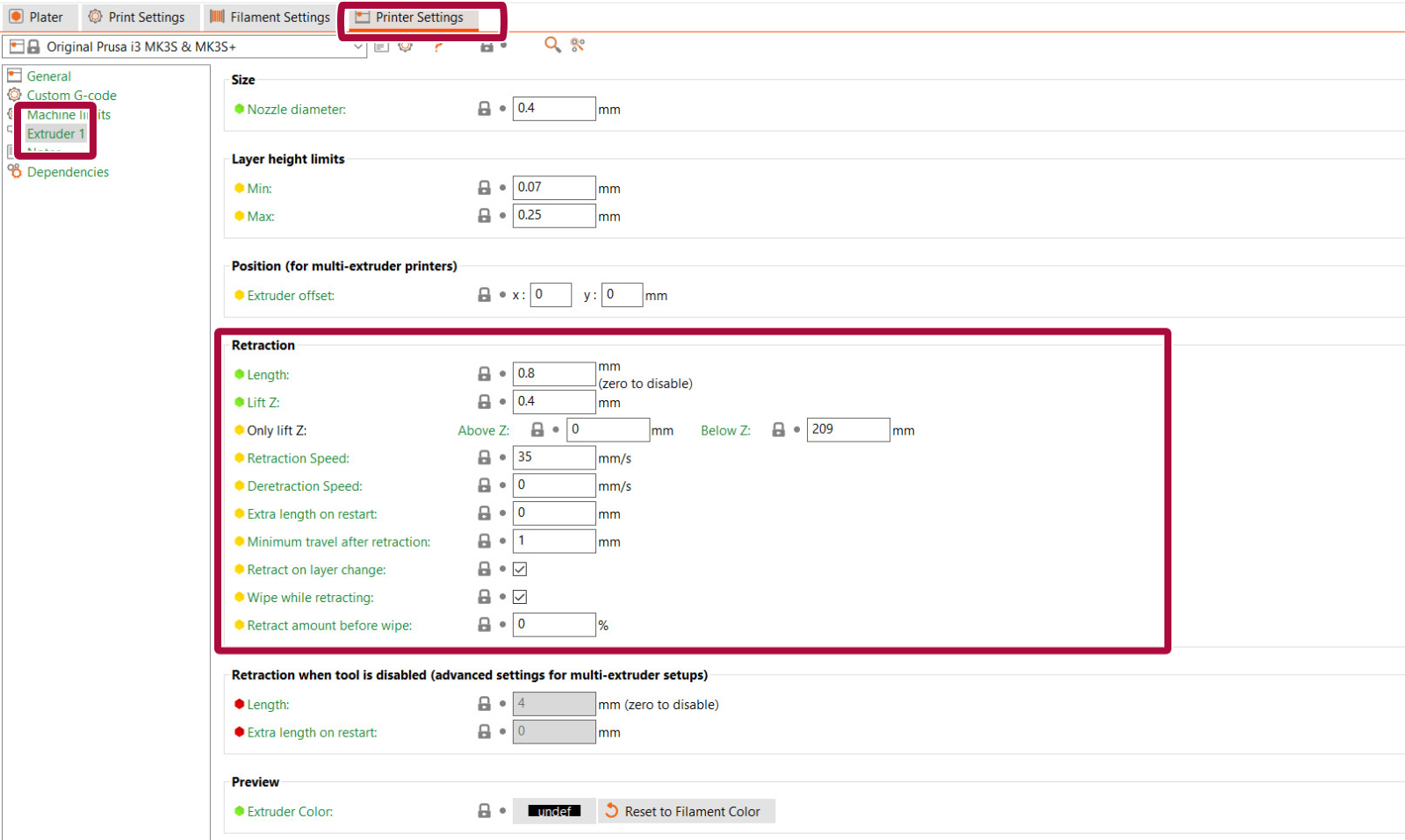

PrusaSlicer settings

You should start by checking a parameter known as Retraction. What does retraction do? When the extruder has finished printing one section/object of your g-code, the filament is pulled back into the nozzle. Once the extruder moves to the next location the printing process continues – the filament is pushed back out and it starts extruding from the nozzle again. Retraction settings can be found in PrusaSlicer in Printer Settings -> Extruder 1.

Flexible filaments usually need longer retractions, because the material stretches while being pulled back to the nozzle. Flexible materials are a special case and can need a lot of tweaking and tuning.

The retraction settings are:

- Retraction length: Amount that the filament is pulled back when a retraction is triggered. On the MK2.5/S and MK3/S/+, the retraction length should be a maximum of 2 mm.

- Lift z: lifts the extruder during movement. Having this setting lower will improve stringing. Note that disabling this feature may cause the nozzle to hit the printed part.

- Retraction Speed: Extruder motor speed on retraction. A higher value improves stringing, but if it is too high it may skip steps in the motor.

- Minimum travel after retraction: Amount of move that will trigger a retraction (mm). The preset number in PrusaSlicer is 1 mm, which is a low amount. Having this number higher will get lower printing times, but increase oozing and stringing.

- Retract on layer change: Activates retraction when the layer changes to the next one. It is recommended to leave this option on.

- Wipe while retracting: Moves the nozzle (wipe) while the retraction is happening. It is recommended to leave this option on.

- Retract amount before wiping: This option does a quick retract before doing the wiping movement. More suitable for the Original Prusa MINI/MINI+.

Other settings that affect retraction:

- Only retract when crossing perimeters: (Print settings -> Infill -> Advanced): Disables retraction when the travel path does not exceed the upper layer's perimeter. Any oozing that happens will be within the walls and should be invisible.

- Avoid crossing perimeters: (Print settings -> Layers and perimeters -> Quality): Optimize travel moves in order to minimize the crossing of perimeters. This will lower the stringing amount, especially in the MINI/MINI+.

- Sequential printing: (Print settings -> Output options -> Sequential printing): Printing each object individually has a smaller chance of causing stringing between the parts. When using this feature, PrusaSlicer will warn you of any possibility of the extruder colliding with an already printed part, but follow the print closely.

- Nozzle temperature: (Filament settings -> Filament -> Nozzle): Lowering the temperature decreases the occurrence of strings. Try decreasing the nozzle temperature by 5 – 10°C and check whether there’s less stringing.

Filament

Try using a different spool than the one that is causing the stringing. The filament might have gathered moisture, which will cause a lot of stringing.

Hotend

Stringing in the nozzle might be caused by a heat dissipation issue in the nozzle. Try re-applying thermal paste on the threads between the heatbreak and the heatsink.

If you have recently changed any component in the hotend, it is also possible that some individual parts are not in place. Go over the assembly of the hotend and check for any parts that may be different from the instructions.

Enough settings, pass me my heat-gun!

If you don’t feel like tweaking any of the settings, well, then there is an alternative. You can get rid of the strings with a heat gun (or often with a lighter – but be very careful). Set your heat-gun to around 200 °C and aim at the strings for one or two seconds. This will melt the strings, and the printed object should remain undamaged. Do not leave the heat source on the printed model for longer than one or two seconds, as this may deform the part.

Comments

Still have questions?

If you have a question about something that isn't covered here, check out our additional resources.

And if that doesn't do the trick, you can send an inquiry to [email protected] or through the button below.