- Čeština

- Español

- Italiano

- Deutsch

- Polski

- Français

- 日本語

- Home

- Troubleshooting

- Print Quality Troubleshooting

- Poor bridging

Poor bridging

- Print Quality Troubleshooting

- Bad looking surface above supports

- Broken supports (SL1/SL1S)

- De-lamination / separated layers (SL1/SL1S)

- Failing supports

- Firmware update failed #10534 (SL1)

- First layer issues

- Ghosting

- Holes in print (SL1/SL1S)

- Layer separation and splitting FDM

- Layer shifting

- Object missing details

- Poor bridging

- How to fix it

- Print detached from supports (SL1/SL1S)

- Print doesn't appear / Resin does not solidify

- Prints breaking away from the platform

- Problems with infill

- Removing and object stuck to the bottom of the tank

- Sample G-codes

- Scratches/bubbles on prints (SL1/SL1S)

- Skewed / deformed prints (SL1/SL1S)

- Stringing and oozing

- Temperature sensor failed #10205 (SL1/SL1S)

- The Benchy hull line

- Under-extrusion

- Visible layers (SL1/SL1S)

- Warped layers (SL1/SL1S)

- Warping

- Watertight prints

- Printer troubleshooting

- QR Error codes

- Print Error Messages

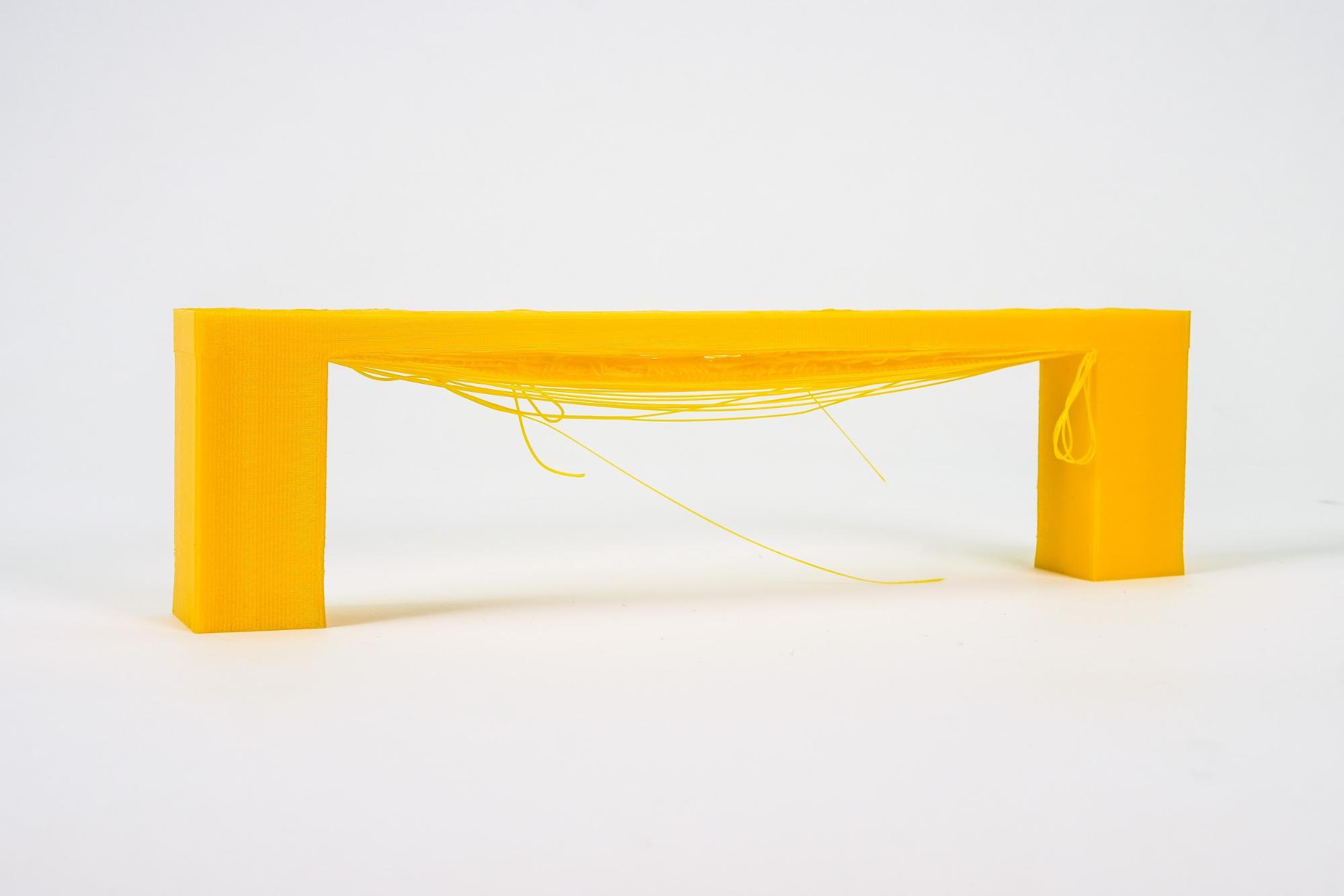

Bridging is a term for printing layers over thin air without the use of supports. It may sound like an impossible feat, but with our MK2 and MK3 printers, it’s not that difficult. Keep in mind that the best results are achieved only over short distances because the printer’s fans need to cool the extruded plastic mid-air in order to create a solid connection. There are three key settings for printing good looking bridged layers: PrusaSlicer settings, speed, and cooling.

The typical problem of bridging layers is sagging or drooping as seen in the photo above.

How to fix it

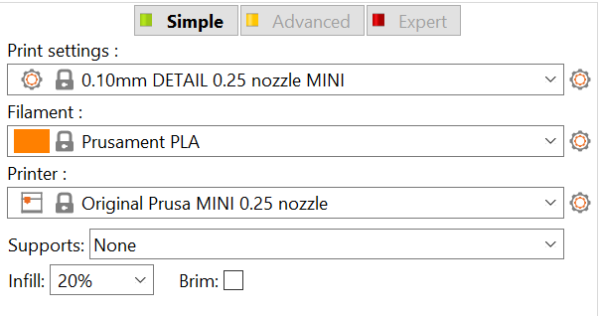

To access some settings/parameters in PrusaSlicer, you must be in 'Advanced' or 'Expert' mode. You can switch to a different mode using the buttons in the right panel or by going to Configuration -> Mode -> Simple/Advanced/Expert. For more information please see Simple, Advanced, Expert modes.

Bridging flow

Bridging flow

The best way to prevent the layers from breaking in bridging mode is to change the “Bridging flow” setting in the PrusaSlicer. The first bridging layer should be done with a lower flow of the material. Open the settings in PrusaSlicer by right-clicking the model, then go to Object settings – Advanced – Bridge flow ratio. We recommend using lower speed for printing bridges and also lower bridging flow. The idea is to “pull” the string of extruded filament behind the nozzle, so it drops less. The ideal approach is to download bridging test models, for example, this one, put it in the slicer several times, and set up a different flow for every model. This should be a relatively quick way how to find correct settings for your printer/material without the need to perform many test prints.

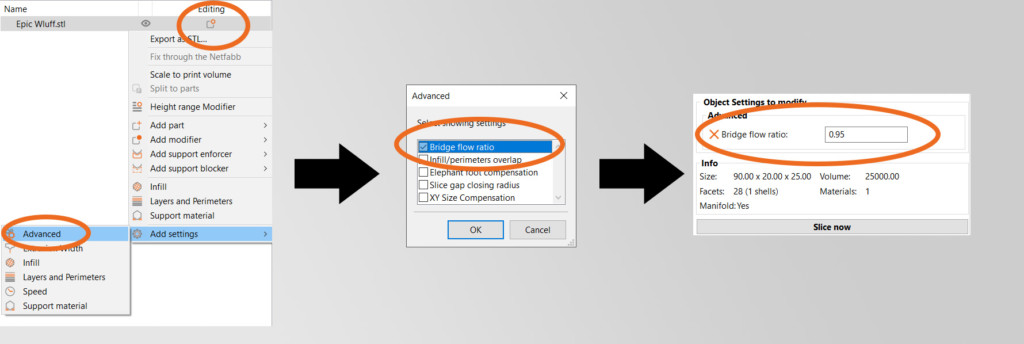

Tweak the speeds in PrusaSlicer

Right-click the object in the 3D view or click on the Editing icon in the Object list to open the context menu. Then select Add settings - Speed - Bridges and tweak the speed for printing bridges.

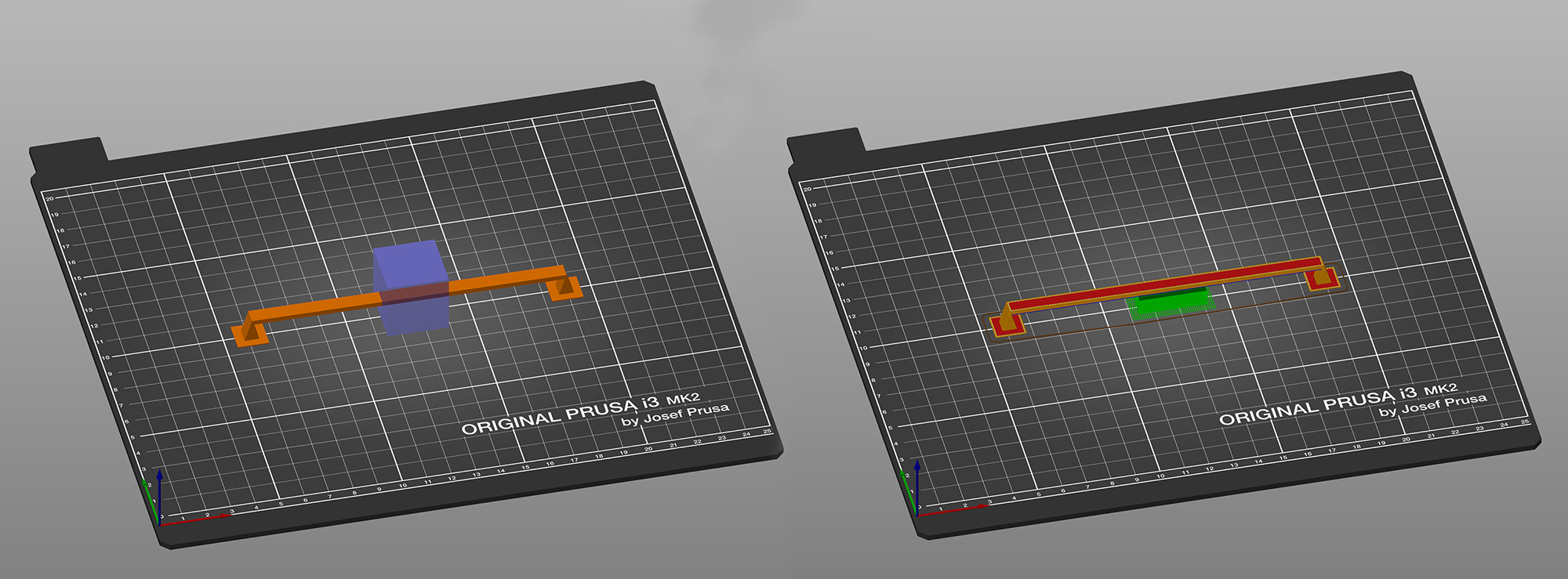

Enforce supports half-way through the bridge

If the bridge is very long, you can use support enforcers to create a support island half-way through. Right-click on the model in the 3D view and select Add support enforcer - Box. Then transform the box using the move, rotate and scale tools.

Change the orientation of the object

The best solution is to change the orientation of the object (rotate it) until you get rid of the bridges completely and you don’t have to worry about bridges or supports. It won’t be possible in many cases, but the rule of thumb here is to try to avoid bridges and supports completely.

Comments

Still have questions?

If you have a question about something that isn't covered here, check out our additional resources.

And if that doesn't do the trick, you can send an inquiry to [email protected] or through the button below.